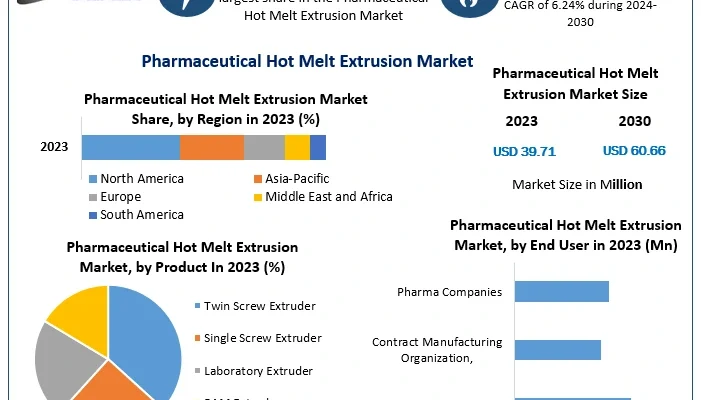

Global Pharmaceutical Hot Melt Extrusion Market Size Projected to Reach USD 60.66 Million by 2030

Innovations in Drug Delivery and Enhanced Bioavailability Drive Market Growth

The global pharmaceutical hot melt extrusion (HME) market, valued at USD 39.71 million in 2023, is anticipated to grow at a Compound Annual Growth Rate (CAGR) of 6.24%, reaching approximately USD 60.66 million by 2030.

Market Definition and Estimation

Hot melt extrusion is a process that applies heat and pressure to melt polymers, forcing them through an orifice to create continuous shapes. Initially prevalent in industries like rubber, plastics, and food processing, HME has gained traction in the pharmaceutical sector for its ability to enhance the bioavailability of active pharmaceutical ingredients (APIs). This technique is instrumental in developing solid dosage forms and drug-eluting devices, such as intraocular implants and transdermal patches.

Get Sample Copy Of The Report Including (TOC, Charts)https://www.maximizemarketresearch.com/request-sample/37193/

Drivers of Market Growth and Opportunities

Several factors are propelling the growth of the pharmaceutical HME market:

-

Development of Drugs with Challenged Bioavailability: The rise in novel drugs with poor solubility and bioavailability has led to the adoption of HME processes in drug delivery systems, particularly in solid dosage forms and transdermal patches.

-

Technological Advancements: The ability to modify functional parameters, such as screw elements and die plates, allows for optimized manufacturing processes, making HME a preferred choice over traditional techniques.

-

Increased Manufacturer Awareness: Growing recognition of HME’s advantages, including improved drug solubility and controlled release profiles, has led to its widespread adoption in pharmaceutical manufacturing.

-

Regulatory Support: Regulatory bodies are increasingly endorsing HME due to its continuous manufacturing process, which aligns with quality-by-design (QbD) principles, ensuring consistent product quality.

Segmentation Analysis

The pharmaceutical HME market is segmented based on various criteria to understand its diverse applications and components:

-

By Product:

- Equipment: Extruders, feeders, and other ancillary equipment essential for the HME process.

- Materials: Polymers, active pharmaceutical ingredients (APIs), and other excipients used in the extrusion process.

-

By Application:

- Drug Delivery: Formulation of solid dispersions, controlled-release tablets, and bioavailability enhancement.

- Medical Devices: Production of drug-eluting implants and transdermal systems.

-

By End-User:

- Pharmaceutical Companies: Utilizing HME for drug formulation and development.

- Research Organizations: Engaged in studying and optimizing HME processes for novel applications.

Country-Level Insights

-

United States: The U.S. leads in adopting HME technology, driven by substantial investments in pharmaceutical research and development. The country’s focus on innovative drug delivery systems and the presence of major pharmaceutical companies contribute to market growth.

-

Germany: As a hub for pharmaceutical manufacturing and engineering excellence, Germany has embraced HME technology. Collaborative efforts between research institutions and industry players have fostered advancements in drug formulation techniques.

Competitive Landscape

The pharmaceutical HME market is characterized by the presence of key players focusing on technological innovations and strategic collaborations:

-

Coperion GmbH: Specializes in designing and manufacturing extrusion equipment tailored for pharmaceutical applications, emphasizing continuous processing and scalability.

-

Thermo Fisher Scientific Inc.: Offers a range of HME equipment and services, supporting drug development from lab-scale to commercial production.

-

GEA Group: Provides integrated HME solutions, combining extrusion technology with process analytical tools to ensure product quality and efficiency.

-

Baker Perkins Ltd.: Focuses on twin-screw extruders for pharmaceutical applications, facilitating the development of novel drug delivery systems.

The global pharmaceutical hot melt extrusion market is on a robust growth trajectory, driven by technological advancements, the need for enhanced drug bioavailability, and supportive regulatory frameworks. As pharmaceutical companies continue to seek innovative drug delivery solutions, HME stands out as a pivotal technology, offering efficiency, scalability, and improved therapeutic outcomes.

For more detailed insights, please visit : https://www.maximizemarketresearch.com/market-report/pharmaceutical-hot-melt-extrusion-market/37193/