High-output Automotive Alternators are essential components for vehicles and machinery that require more electrical power than what standard factory alternators can supply. From upgraded sound systems and winches in off-road trucks to power-hungry emergency lights and refrigeration units in commercial fleets, these alternators deliver consistent, high-amperage output to keep all systems running efficiently. By producing greater current, they ensure stable voltage under heavy load, extending battery life and preventing electrical dropouts in demanding conditions.

Unlike standard alternators designed for basic driving needs, high-output variants are engineered with enhanced windings, heavy-duty rectifiers, and improved cooling mechanisms. This robust design allows them to operate at peak performance even in extreme environments, whether it’s a desert-bound RV, a mobile medical unit, or a work truck with aftermarket electrical accessories. As modern vehicles and equipment continue to add more electronic features, the high-output alternator has become a crucial upgrade to ensure reliability and energy efficiency.

Global High-Output Alternator Market Growth Drivers & Opportunity

High-Output Automotive Alternator Market Electrification & Vehicle Complexity

As vehicles become increasingly electrified, especially with the rise of electric and hybrid models, onboard electronics—from infotainment to ADAS (advanced driver assistance systems)—require greater electrical output. Standard alternators often struggle to keep up, making high-output models the go-to choice for modern automotive electrical needs.

High-Output Automotive Alternator Market Industrial Demand & Backup Systems

Beyond the automotive industry, industrial sectors and backup power systems demand consistent and high current output. Heavy machinery, emergency generators, and renewable energy setups require alternators that can handle variable and peak loads reliably. High-output Automotive Alternators are playing an increasing role in supporting these systems, both in grid-connected and off-grid scenarios.

High-Output Automotive Alternator Market Innovation & Regulation

Regulatory mandates around emissions and energy efficiency are pushing manufacturers to innovate. High-output Automotive Alternators are evolving to offer higher efficiency, better thermal management, and smarter electronic regulation. These advancements create further opportunity for both manufacturers and end-users in various sectors.

Global High-Output Alternator Market Segmentation Analysis

The global high-output alternator market can be segmented as follows:

-

By Type: Single-phase and three-phase alternators.

-

By Application: Automotive, industrial, marine, and residential backup power systems.

-

By Region: North America, Europe, Asia Pacific, Latin America, and the Middle East & Africa.

Three-phase alternators currently dominate industrial applications due to their ability to deliver constant and higher power, while single-phase models are commonly found in smaller, consumer-grade installations and vehicles.

Global High-Output Alternator Market Country-Level Analysis: USA & Germany

United States

The U.S. high-output alternator market is among the most mature and dynamic globally. With strong demand in the automotive, RV, and heavy-duty trucking industries, the segment has become increasingly lucrative. The transition toward electric vehicles (EVs), along with stringent energy regulations, has driven adoption across both OEM and aftermarket channels.

Key growth areas include:

-

EV and hybrid vehicle upgrades

-

Commercial fleet electrification

-

Military and specialty vehicle applications

Germany

Germany remains a leader in vehicle engineering and industrial machinery, both of which heavily influence alternator demand. High-output Automotive Alternators are increasingly integrated into German EV platforms, automated manufacturing systems, and industrial backup systems. The country’s focus on renewable energy integration and industrial efficiency also supports the use of robust, high-output charging systems in various applications.

High-Output Alternator Installation Guide

Whether you’re a professional technician or a well-prepared DIY enthusiast, the following steps outline the proper installation procedure for a high-output alternator:

Step 1: Safety First

Always disconnect the battery before working on electrical components. Wear gloves and eye protection. Ensure the engine is off and cool.

Step 2: Disconnect the Battery

Remove the negative battery terminal to prevent electrical shorts.

Step 3: Remove Factory Alternator

Loosen the serpentine belt tensioner and remove the belt. Then unbolt and disconnect the wiring from the old alternator. Label wires if necessary.

Step 4: Prepare for Installation

Compare the new alternator’s mounting points and pulley with the original. Use a belt that is 0.5 to 1 inch shorter if the new alternator has a larger case or pulley.

Step 5: Install High-Output Alternator

Bolt the new unit into place using the original bracket. Connect all wires to the correct terminals. Double-check torque and alignment.

Step 6: Reinstall Belt and Reconnect Battery

Refit the serpentine belt and ensure it is properly tensioned. Reconnect the negative battery terminal.

Step 7: Test the System

Start the vehicle and use a voltmeter to test output voltage. A high-output alternator should produce 13.5V to 14.8V under normal load conditions. Ensure the unit operates quietly and without excessive heat.

Global High-Output Alternator Market Commutator Analysis

Although modern high-output alternators typically use brushless designs, understanding commutators is important for legacy systems or industrial applications that still use them.

A commutator is a rotary switch found in some DC machines and alternators that reverses the current direction between the rotor and the external circuit. It works in tandem with brushes that maintain contact with the rotating surface.

Global High-Output Alternator Market Advantages of Commutator-Based Alternators

-

Simpler control at low speeds

-

Cost-effective in legacy systems

-

Suitable for variable-load conditions

Disadvantages

-

Higher maintenance due to brush wear

-

Heat buildup and friction loss

-

Lower efficiency compared to brushless systems

Global High-Output Alternator Market Modern Trend

High-output brushless alternators are quickly replacing commutator-based models due to better efficiency, longer lifespan, and reduced maintenance. Brushless models use electronic regulation and permanent magnets or field excitation to deliver stable, high-current output with minimal degradation over time.

For Reference : https://www.maximizemarketresearch.com/market-report/global-automotive-alternator-market/28533/

-

Denso Corporation

A global leader in automotive components, Denso manufactures high-output alternators known for their exceptional reliability and energy efficiency in both original equipment and aftermarket sectors. -

Robert Bosch GmbH

Bosch is a long-established powerhouse in automotive technology, producing advanced alternators designed for durability, energy savings, and high-load applications in a range of vehicles. -

Valeo SA

Valeo develops cutting-edge alternator systems tailored for modern vehicles, with a focus on reducing fuel consumption and supporting increasing electronic demands. -

Mitsubishi Electric Corporation

Mitsubishi offers high-output alternators that support the growing needs of hybrid and electric vehicles, integrating compact designs with high-efficiency power output. -

Hitachi Automotive Systems

Known for innovation and precision, Hitachi manufactures robust alternators suited for passenger cars, commercial vehicles, and electric mobility platforms. -

Prestolite Electric / Leece-Neville

Specializing in heavy-duty applications, Prestolite’s Leece-Neville brand delivers high-output alternators for military, marine, construction, and commercial fleet vehicles. -

Cummins Inc.

Cummins designs high-performance alternators to power off-highway vehicles, industrial equipment, and integrated engine systems with dependable, high-output capabilities. -

ABB Ltd.

ABB provides alternators and generators for industrial and infrastructure applications, emphasizing energy efficiency and continuous high-load performance. -

Siemens AG

Siemens manufactures alternators for high-demand environments, including power generation and large-scale industrial systems, using innovative materials and smart controls. -

Mecc Alte

A specialist in synchronous alternators, Mecc Alte serves global markets with durable power solutions for marine, construction, and off-grid energy applications.

Global High-Output Alternator Market Conclusion

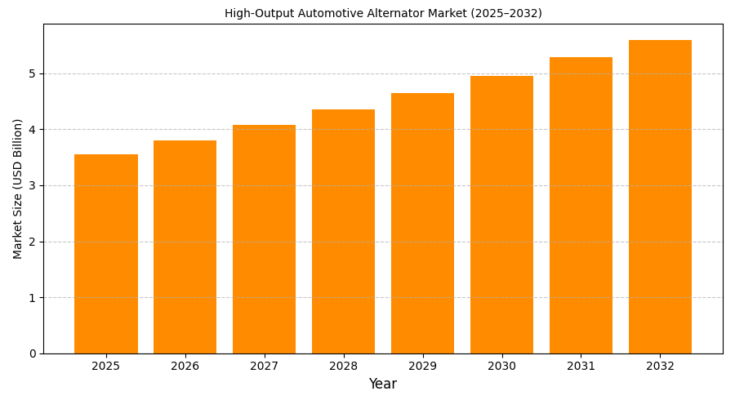

High-output Automotive Alternators are now essential in both advanced automotive systems and demanding industrial environments. With a global market valuation set to surpass USD 4 billion in the next few years, opportunities in both OEM and aftermarket segments are growing rapidly.

For professionals, understanding the technical advantages, regional demand patterns, and proper installation techniques ensures maximum performance and longevity from upgraded systems.

As vehicles and industries continue to electrify, high-output alternators will remain a crucial component in supporting the power infrastructure of the modern world.

Related Report: https://researchmaximize.com/global-automotive-electronics-sensors-market-size-set-to-surge-usd-76-7-billion-by-2030/