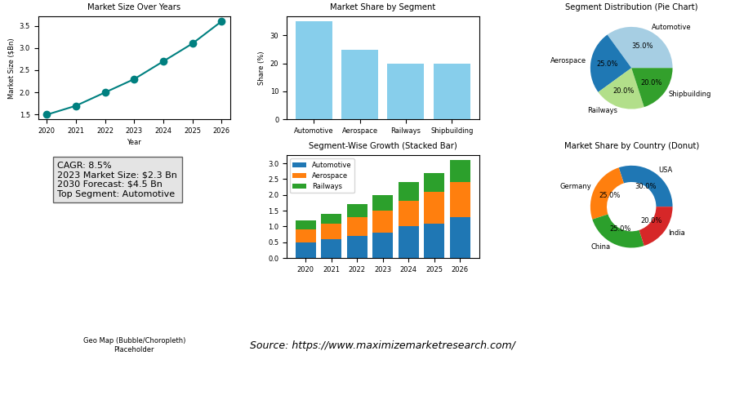

The global Friction Stir Welding (FSW) market is poised for significant expansion, projected to grow from USD 248.12 million in 2023 to approximately USD 367.05 million by 2030, at a CAGR of 5.75% over the forecast period.

Friction Stir Welding Market Estimation & Definition

Friction Stir Welding (FSW) is a solid-state joining process where a non-consumable rotating tool generates frictional heat and plastic deformation at the joint. This process enables the joining of materials without melting, resulting in superior mechanical properties, lower distortion, and cost-effective manufacturing.

The market size is estimated at USD 248.12 million in 2023 and is expected to reach USD 367.05 million by 2030. This growth is fueled by rising demand in sectors that require lightweight, high-strength, and precise joining technologies.

Friction Stir Welding Market Growth Drivers & Opportunities

Automotive & Transportation

As the global automotive industry undergoes a transformation toward electric vehicles and lighter vehicles, FSW offers exceptional joining for aluminum components, battery enclosures, and structural parts. It enhances fatigue resistance and reduces energy input, making it ideal for EV production lines.

Railway Infrastructure

The railway industry accounted for the largest share of the friction stir welding market in 2023. The technology ensures low-maintenance, durable welds required in long railway panels and chassis. It also supports rapid track fabrication, thereby optimizing infrastructure projects.

Aerospace & Defense

FSW enables defect-free welding of critical aerospace components such as fuselage sections, ribs, and wing panels. The ability to join dissimilar metals like aluminum and titanium without degrading properties is key in aerospace and defense applications.

Electronics & Emerging Applications

Growing miniaturization in electronics and demand for high-precision assemblies are creating opportunities for FSW. It is being used in heat sink assemblies, enclosures, and EMI shielding components, offering clean, contamination-free welds.

Technological Innovation

Developments in machine technology such as adjustable and self-reacting tools are expanding the application scope. Integration with automation and robotics is increasing productivity and consistency, particularly in mass production environments.

Regional Growth Outlook

While North America and Europe remain mature markets with established applications, Asia Pacific is emerging as a hotspot for future growth. Rapid industrialization, rising vehicle production, and infrastructure investments are driving adoption across the region.

Friction Stir Welding Market Segmentation Analysis

The friction stir welding market is segmented by equipment type, material type, and application.

By Equipment Type:

-

Fixed FSW Equipment: Common in large-scale production facilities with consistent joining requirements.

-

Adjustable FSW Equipment: Gaining popularity due to versatility across different thicknesses and joint configurations.

-

Self-reacting FSW Equipment: Increasingly used in aerospace and thick panel welding.

By Material Type:

-

Aluminum Alloys: Most widely used due to light weight and weldability.

-

Magnesium

-

Titanium

-

Copper

-

Steel Alloys

-

Others

Friction Stir Welding Market, Key Players:

1. Concurrent Technologies Corp. – USA

2. FOOKE GmbH – Germany

3. Gatwick Technologies Ltd. – UK

4. HFW Solutions LLC – USA

5. Hitachi High-Technologies Corp. – Japan

6. Manufacturing Technology, Inc. (MTI) – USA

7. Midea Group (KUKA AG) – China/Germany

8. Norsk Hydro ASA – Norway

9. PaR Systems LLC – USA

10. Yamazaki Mazak Corp. – Japan

11. Beijing FSW Technology Co., Ltd. – China

12. The ESAB Group, Inc. – USA (part of Colfax Corporation)

13. KUKA Systems GmbH – Germany

14. MegaStir – USA

15. Eta Technology Private Limited – India

16. Grenzebach Maschinenbau GmbH – Germany

17. Colfax Corporation (ESAB) – USA

18. Schlumberger Limited – USA

Aluminum remains dominant due to its use in automotive, aerospace, and electronic enclosures.

By Application:

-

Automotive

-

Aerospace

-

Railways

-

Shipbuilding

-

Others

In 2023, the railways segment accounted for the highest share, followed closely by automotive and aerospace applications.

Friction Stir Welding Market Country-Level Analysis: USA & Germany

United States

The U.S. market benefits from technological maturity, a strong aerospace sector, and advanced automotive R&D. Adoption of FSW is rising in both commercial and defense aircraft manufacturing. The country is also witnessing increasing applications in EV battery fabrication and high-volume electronics production.

The U.S. is also advancing in robotic FSW systems, especially for precision components and modular fabrication in manufacturing hubs.

Germany

Germany leads the European market with its robust automotive and industrial base. High-precision welding requirements in electric vehicle platforms, battery housings, and lightweight structures make FSW a favored technology.

Industry 4.0 initiatives and government-backed support for green manufacturing practices are also reinforcing FSW’s role in the German manufacturing landscape.

Friction Stir Welding Market Commutator Analysis

Friction Stir Welding is gaining attention in the production of commutators, essential components in electric motors used across industrial, automotive, and appliance sectors.

Benefits of FSW in Commutator Manufacturing:

-

High Conductivity Maintenance: By avoiding melting, FSW retains original material properties—essential for conducting components like copper segments.

-

Improved Joint Integrity: FSW provides stronger, defect-free welds compared to soldering or mechanical joining.

-

Thermal Stability: FSW generates less residual heat, preventing warping in fine parts such as commutator laminations.

-

Process Automation: FSW lends itself well to automated production lines, increasing throughput and reducing human error.

As demand for electric motors rises in EVs and home appliances, FSW adoption in commutator manufacturing is expected to increase. The process offers lower cycle times and improved part reliability—critical for high-speed, high-torque applications.

Friction Stir Welding Market Press Release Conclusion

The global friction stir welding market is undergoing a strategic evolution, backed by demand for efficient, durable, and clean joining technologies. With widespread applications in railway infrastructure, automotive EV platforms, aerospace panels, and electronics, FSW is increasingly viewed as a standard in precision welding.

The projected market growth to USD 367.05 million by 2030 reflects not only expanding industrial use cases but also technological breakthroughs in FSW machinery and materials science.

North America and Europe will continue to be key adopters, while Asia Pacific offers untapped potential with its growing manufacturing base. The technology’s emerging role in commutator production and micro-weld assemblies further broadens its addressable market.

In an era where sustainability, strength, and precision are paramount, friction stir welding offers industries a scalable and future-ready solution.

Know more About the Spark Plug Market

Spark Plug Market Size Globally Will Reach 4.73 billion by 2030